Copper is one of the most widely used metals in the world and has been used for countless purposes throughout history. One particular application of copper that dates back to ancient times is copper wire. Nowadays, copper wire is used in countless applications, from electrical wiring and electronics to jewelry making and art. This blog post will explore the benefits of using bare copper wire and the manufacturing excellence required to produce it.

1. Benefits of Bare Copper Wire

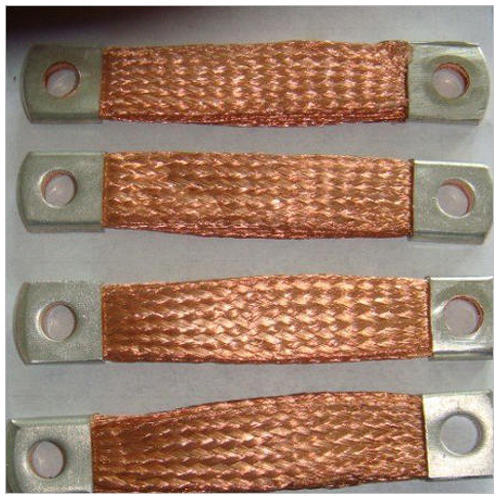

Bare copper wire is an electrical wire with no insulation coating, making it an excellent conductor of electricity, even better than some of its insulated counterparts. Bare copper wire is also more durable and long-lasting than insulated wire and is resistant to high temperatures and corrosion. Furthermore, bare copper wire is less expensive than insulated wire, making it an ideal choice for commercial and industrial applications.

2. Manufacturing Excellence

The production of high-quality bare copper wire requires manufacturing excellence. The copper used to produce bare copper wire must be pure and impurities-free, and contamination can lead to reduced conductivity and durability. The production process for bare copper wire involves drawing a copper rod through a series of dies, resulting in a decrease in diameter and an increase in length. To produce a high-quality product, the process requires careful monitoring and control of factors such as wire diameter, tension, and temperature.

3. Applications of Bare Copper Wire

Bare copper wire has various applications, including electrical wiring, telecommunications, automotive, and marine industries. It also manufactures motors, transformers, and other electrical components. Bare copper wire is also used in jewelry making, where its natural shine and durability make it an attractive choice. Additionally, it can be used in art, where it can be shaped and molded into unique pieces.

4. Environmental Benefits

Bare copper wire is a highly recyclable and environmentally friendly material. Recycling bare copper wire reduces the amount of waste in landfills and can help to conserve natural resources. Furthermore, producing copper wire from recycled copper requires significantly less energy than producing new copper, reducing carbon footprint.

5. Conclusion

Bare copper wire is an excellent conductor of electricity with numerous benefits over the insulated wire, including improved durability, resistance to temperature and corrosion, and affordability. Producing high-quality bare copper wire requires manufacturing excellence, including using pure copper and carefully monitoring production factors. Bare copper wire has various applications, from electrical wiring to art, and is a highly recyclable and environmentally friendly material. Incorporating bare copper wire into your project can benefit you and the environment.